Heavy Duty Accumulation Conveyor from TKF Uses Single Drive to Control Multiple Accumulation Zones

TKF's zoned accumulation conveyor with roll-to-roll chain driven live rollers (CDLR), is designed to handle medium to heavy-duty loads. The zone lengths can be designed to coincide with the product lengths. The entire conveyor length is then driven by a single power unit. Each accumulation zone is driven by air-operated clutches that are controlled by photo-eyes and solenoids located in each zone. While sensor rollers are available, the all electric sensing eliminates the wear and tear of a sensor roller. The single drive configuration requires less power than multi-drive systems and produces a clean, low maintenance system.

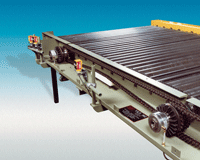

TKF's accumulation conveyor is also designed with each clutch assembly mounted on the side frame of the conveyor, instead of underneath. This creates a very low profile that positions the top of each roller as low as 6 inches off the floor, making it ideal for heavy loads and pallet conveying. It also provides a very accessible location for moving parts, which makes maintenance very easy.

Roller diameters are available in diameters of 1.9 inches, 2.5 inches and 3.5 inches and widths up to 60 inches. Weight loads up to 6000 lbs. are typical.

Welcome to the TKF News Section!

Here you will find additional information regarding our conveyor systems along with Tradeshow appearances!

Please feel free to explore the links below to see what we've been up to!